In-House Design and Manufacturing Capabilities

Introduction to Our In-House Capabilities

We pride ourselves on our state-of-the-art in-house design and manufacturing capabilities, which allow us to deliver high-quality refractory products that meet the specific needs of our clients. By maintaining full control over the design and manufacturing process, we ensure consistent quality, faster turnaround times, and the flexibility to create customized solutions tailored to the unique requirements of various industries, including oil refineries, ethylene plants, power plants, and steel mills.

Our In-House Design and Manufacturing Capabilities

Explore the range of our in-house design and manufacturing capabilities, each tailored to deliver precision, reliability, and optimal performance:

Comprehensive Design Services

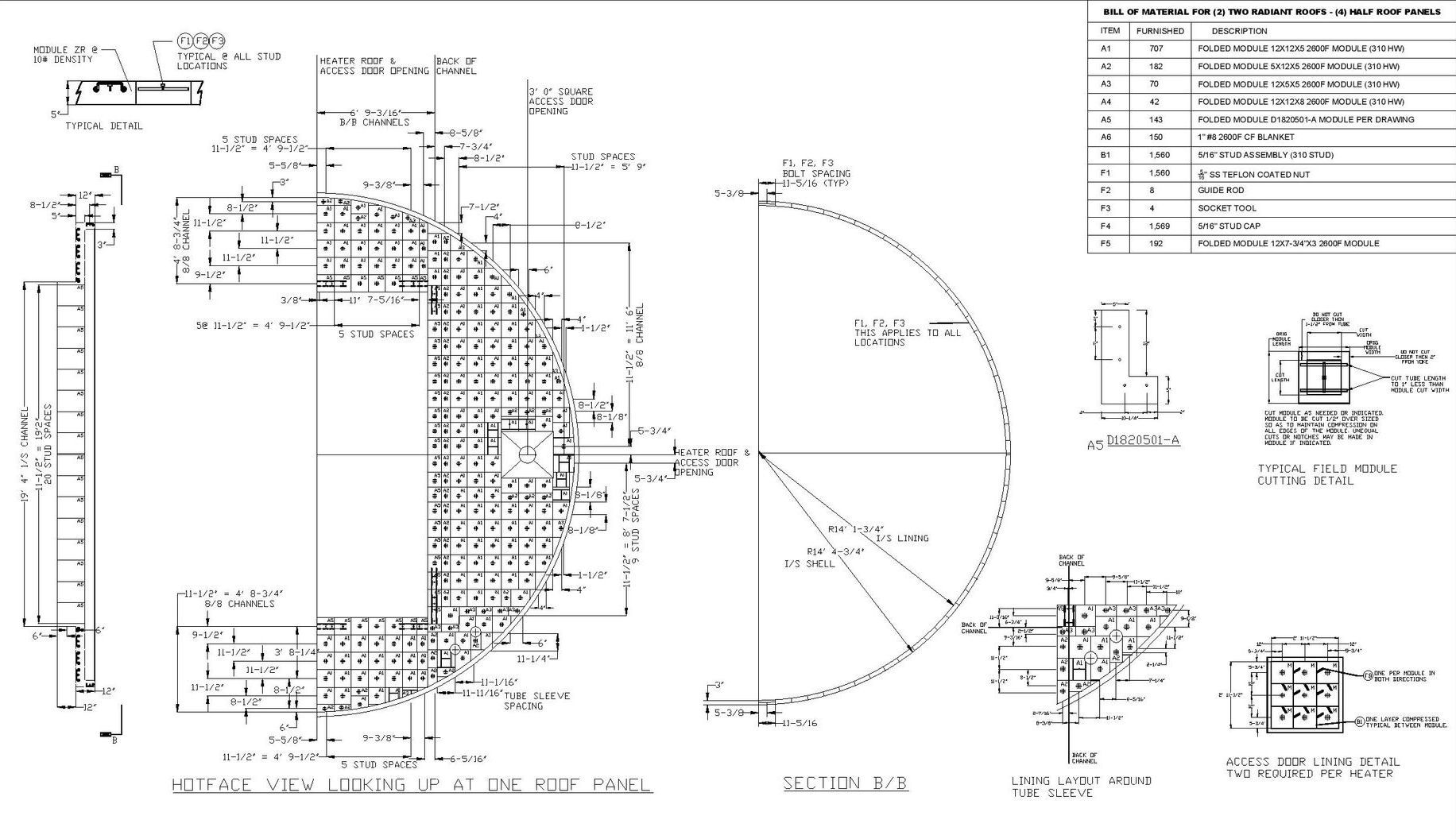

Our experienced design team utilizes advanced software and industry expertise to create detailed designs for a wide range of refractory products. From standard components to complex custom solutions, we ensure that every design meets the highest standards of quality and performance.

Applications and Benefits:

- Customized designs for furnaces, kilns, boilers, and high-temperature equipment

- Enhanced performance and efficiency through precision-engineered solutions

- Reduces lead times and ensures faster project completion

Specifications:

- Use of CAD software and 3D modeling for precise design and visualization

- Ability to create custom shapes, sizes, and configurations based on client specifications

- Collaborative design process to incorporate client feedback and requirements

Advanced Manufacturing Techniques

Our in-house manufacturing capabilities include a wide range of advanced techniques that enable us to produce high-quality refractory products efficiently. We employ state-of-the-art machinery and skilled technicians to ensure every product meets the highest standards of durability and performance.

Key Features and Advantages:

- Precision manufacturing of refractory shapes, modules, and hardware

- Use of advanced equipment such as CNC machines, presses, and kilns

- Stringent quality control measures throughout the manufacturing process

Common Uses:

- Production of standard refractory shapes and custom components for industrial applications

- Manufacturing of specialized products, including burner blocks, peep sights, and insulating fire bricks

- Fabrication of complex assemblies and custom solutions for unique operational needs

Custom Product Development

We offer custom product development services to help clients create bespoke refractory solutions tailored to their specific applications. Our team works closely with clients from concept to completion, ensuring that each product is designed and manufactured to meet exact specifications.

Benefits:

- Development of custom refractory products that address specific operational challenges

- Enhanced product performance through tailored material selection and design optimization

- Ability to prototype, test, and refine products to ensure optimal functionality

Typical Applications:

- Retrofitting existing furnaces, kilns, and reactors with custom refractory solutions

- Installing new custom refractory linings and components

- Modifying and upgrading current refractory setups to improve efficiency and durability

Quality Assurance and Testing

Quality is at the core of everything we do at Applied Refractory. Our in-house quality assurance and testing procedures ensure that every product we manufacture meets the highest standards of performance and reliability. We use a range of testing methods to validate the quality and durability of our refractory products.

Benefits and Applications:

- Comprehensive testing for thermal performance, mechanical strength, and chemical resistance

- Ensures products meet or exceed industry standards and client expectations

- Provides confidence in the reliability and longevity of our refractory solutions

Specifications:

- Testing methods include thermal cycling, mechanical stress testing, and chemical exposure analysis

- Documentation and reporting provided for all testing procedures

- Continuous improvement practices to enhance product quality and performance

Tailored Refractory Solutions

Our in-house design and manufacturing capabilities allow us to provide tailored refractory solutions that meet your specific needs. Whether you require custom shapes, specialized materials, or a completely new product design, our team is here to help. Contact us today to discuss your custom refractory needs and discover how we can provide a solution that’s perfect for your project.

Why Choose Applied Refractory for In-House Design and Manufacturing?

When you choose Applied Refractory, you’re partnering with a company that prioritizes quality, innovation, and customer satisfaction. Here’s why our customers trust us:

- Full Control Over Production: Our in-house capabilities mean we control every step of the design and manufacturing process, ensuring consistent quality and precision.

- High-Quality Materials: We use only the best refractory materials to produce products that offer superior durability and thermal resistance.

- Expert Team: Our skilled engineers and technicians are dedicated to providing the best possible solutions for your refractory needs, from initial design to final delivery.

- Quick Turnaround: With all processes handled in-house, we offer faster turnaround times to keep your projects on schedule.

Get a Quote Today

Ready to take advantage of our in-house design and manufacturing capabilities? Contact us today to request a quote or learn more about how our custom solutions can meet your refractory needs. Our team is here to help you find the ideal solution for your high-temperature applications.