Refractory Hardware

Introduction to Refractory Hardware

Applied Refractory provides a comprehensive range of refractory hardware designed to support high-temperature insulation materials and enhance the durability of refractory installations. Our hardware is engineered to withstand extreme temperatures and harsh conditions, making it ideal for various industrial applications, including oil refineries, ethylene plants, power plants, forges, and steel mills.

Our Range of Refractory Hardware

Explore our extensive selection of refractory hardware, each crafted to meet the highest standards of quality and performance:

Refractory Anchors

Refractory anchors are essential components used to secure refractory linings in high-temperature environments. Our anchors are designed to provide maximum support and stability, ensuring the longevity and effectiveness of refractory materials.

Applications and Benefits:

- Secure refractory linings in furnaces, kilns, and other high-temperature equipment

- Provide structural integrity and prevent material slippage

- Available in various shapes and sizes to accommodate different installation requirements

Specifications:

- Material options: 304SS, 316SS, 310SS, Inconel alloys, and more

- Available in standard configurations like V-anchor, Y-anchor, and U-anchor

- Custom designs available to meet specific project needs

Brick Tie Backs

Our brick tie-backs are designed to provide additional support for refractory brick installations, ensuring that bricks remain securely in place under high-stress conditions. These components are crucial for maintaining the structural integrity of refractory linings.

Key Features and Advantages:

- Prevents brick movement and enhances lining stability

- Suitable for use in high-temperature and high-load environments

- Available in a variety of sizes and materials to suit different applications

Common Uses:

- Reinforcing brick linings in furnaces, kilns, and reactors

- Providing support in areas exposed to thermal cycling and mechanical stress

- Ideal for use in industrial settings requiring robust refractory solutions

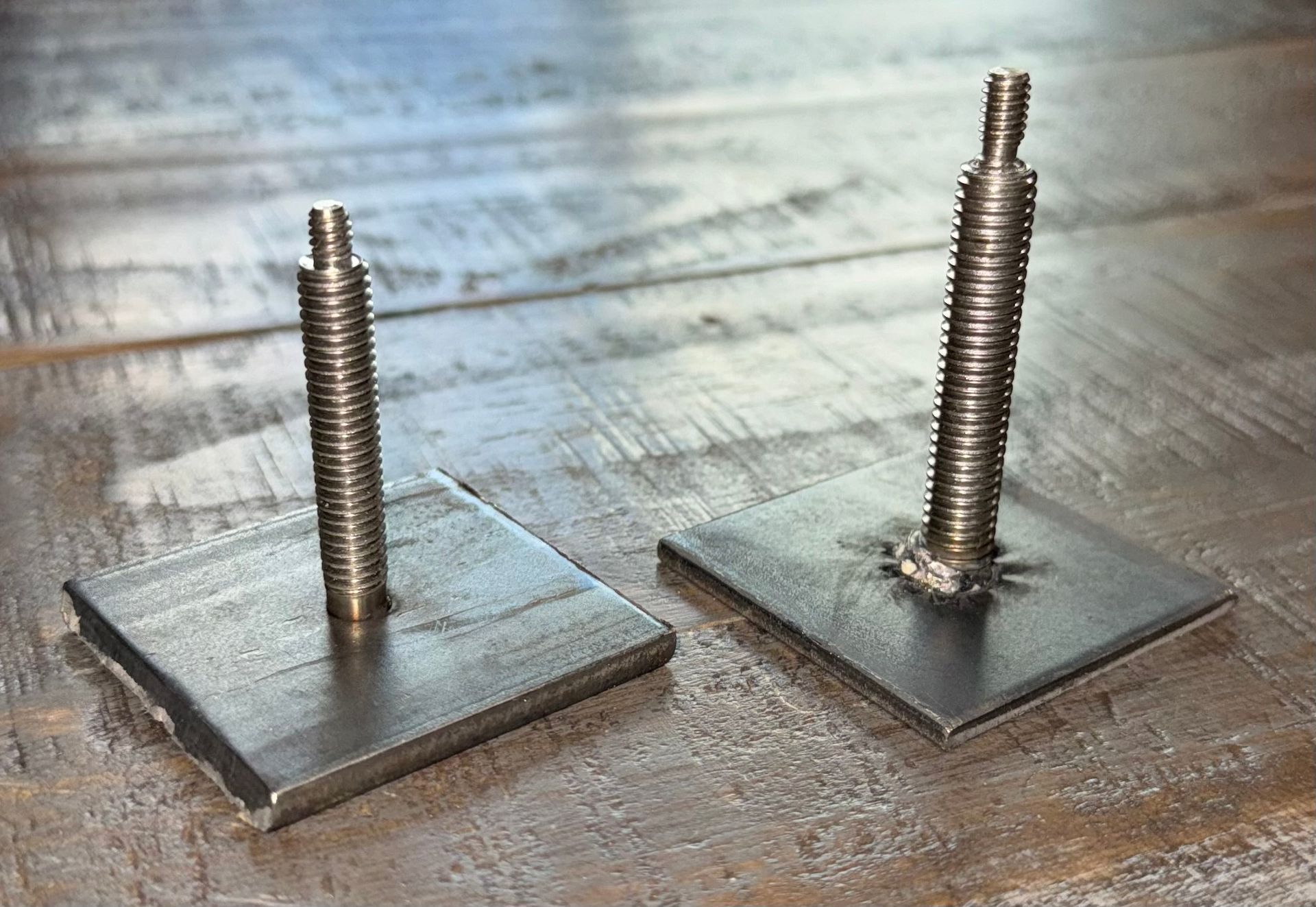

Stainless & Inconel Studs, Nuts, and Washers

Applied Refractory offers a wide range of stainless steel and Inconel studs, nuts, and washers designed for use in high-temperature applications. These fasteners provide reliable performance and corrosion resistance, ensuring the stability of refractory installations.

Benefits:

- High resistance to corrosion and oxidation in extreme temperatures

- Ensures secure attachment of refractory materials and hardware

- Available in various sizes and thread configurations for different applications

Typical Applications:

- Securing refractory linings in furnaces, kilns, and boilers

- Fastening refractory anchors, brick tie-backs, and other hardware components

- Used in environments requiring high strength and durability

Our ceramic fiber studs, washers, and anchor systems are designed for use with ceramic fiber insulation products, providing a secure attachment that withstands high temperatures and thermal cycling.

Benefits and Applications:

- Designed to anchor ceramic fiber blankets, modules, and boards

- Provides secure attachment while allowing for thermal expansion and contraction

- Ideal for use in furnaces, kilns, and other high-temperature applications

Specifications:

- Available in various lengths and diameters to accommodate different insulation thicknesses

- Manufactured from high-temperature alloys for durability and longevity

- Custom configurations available for specific project requirements

Module Attachment Hardware

We provide a range of module attachment hardware, including weld stud assemblies, shoot-and-go assemblies, H hangars, and time systems. These components are designed to securely attach ceramic fiber modules and other refractory products, ensuring stable and reliable installations.

Key Features:

- Secure attachment of ceramic fiber modules in high-temperature environments

- Compatible with various refractory products and installation methods

- Available in standard and custom configurations to meet project needs

Applications:

- Installing ceramic fiber modules in furnaces, kilns, and other thermal equipment

- Providing a secure, long-lasting attachment that resists thermal cycling

- Used in a variety of industries, including petrochemical, power generation, and metalworking

Custom Refractory Hardware Solutions

At Applied Refractory, we understand that each project has unique requirements. That's why we offer custom refractory hardware solutions designed to meet your specific needs. Whether you need a special material, size, or configuration, our team is ready to work with you to create the perfect hardware solution for your application. Contact us today to discuss your custom refractory hardware requirements.

Why Choose Applied Refractory for Refractory Hardware?

Choosing Applied Refractory means partnering with a company committed to quality, reliability, and customer satisfaction. Here's why our customers choose us:

- Distributed Hardware: Variety of hardware..., allowing us to maintain strict quality control and offer competitive pricing.

- High-Quality Materials: Our hardware is made from premium materials designed to withstand extreme temperatures and harsh environments.

- Expert Support: Our experienced team is available to guide you through product selection, customization, and installation, ensuring you get the right solution for your needs.

- Fast Turnaround:

With our in-house production capabilities, we provide quick delivery times to keep your projects on schedule.

Frequently Asked Questions About Refractory Hardware

When working with high-temperature applications, it’s natural to have questions about performance, durability, and installation. At Applied Refractory, we want to make sure you have the right information before starting your project. Below are answers to some of the most common questions we receive from clients across industries.

What Types of Industries Use Refractory Materials in Houston, TX?

Refractory materials are used in a wide range of industries where equipment must withstand extreme heat. Common applications include oil refineries, petrochemical plants, steel mills, power generation, and manufacturing facilities. If your business requires reliable solutions for high-temperature operations, our refractory materials in Houston, TX, are engineered to meet these demanding needs.

How Do I Know Which Hardware or Material Is Right for My Project?

Choosing the right hardware depends on the operating conditions of your equipment, including temperature range, load, and environmental factors. Our team works with you to assess your project requirements and recommend the most effective refractory hardware. For personalized guidance, you can reach out to us directly through our contact page.

Can Refractory Hardware Be Customized?

Yes. Many projects require unique specifications that go beyond standard options. At Applied Refractory, we provide custom hardware solutions designed for your application. Whether you need a specific alloy, size, or configuration, our in-house team can create durable components that ensure reliable performance in even the toughest environments.

How Long Do Refractory Materials Typically Last?

The lifespan of refractory products depends on factors like operating conditions, installation quality, and maintenance. In industrial settings, well-installed refractory hardware can last years while maintaining performance. Our refractory materials in Houston, TX, are manufactured with premium alloys to resist wear, extending the durability of your installations.

Why Should I Choose Applied Refractory Over Other Suppliers?

With years of experience and a strong reputation for quality, Applied Refractory provides hardware built to endure harsh conditions. We use high-grade materials, offer custom solutions, and maintain quick turnaround times to keep your projects on schedule. By choosing us, you gain access to expert support and products tailored to your needs.

Get a Quote Today

Ready to find the perfect refractory hardware for your application? Contact us today to request a quote or learn more about our products and services. Our team is here to help you find the ideal solution for your high-temperature insulation needs.