Distribution Partners

Introduction to Distributed Products

We are proud to be a full-line distributor of high-quality refractory products from some of the most trusted brands in the industry. By partnering with leading manufacturers, we offer a comprehensive range of refractory materials designed to meet the diverse needs of industries such as oil refineries, ethylene plants, power plants, steel mills, and more. Our distributed products provide exceptional durability, thermal efficiency, and reliability for various high-temperature applications.

Our Range of Distributed Products

Explore our extensive selection of distributed refractory products, each crafted to meet the highest standards of quality and performance:

Allied Mineral Products

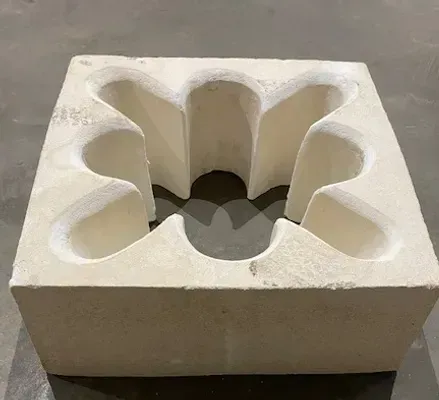

As a full-line distributor for Allied Mineral Products, we offer a variety of monolithic refractories and precast shapes designed to provide superior performance in high-temperature environments. Allied Mineral Products are known for their durability, thermal stability, and resistance to chemical attack, making them ideal for various industrial applications.

Applications and Benefits:

- Monolithic refractories for furnaces, kilns, and ladles

- Precast shapes for specialized applications, such as burners and nozzles

- High resistance to thermal shock, abrasion, and chemical corrosion

Key Features:

- Available in various formulations to suit specific temperature and environmental conditions

- Custom shapes and sizes are available upon request

- Trusted performance in demanding industries like steel, foundry, and petrochemical

WESCO Refractories

WESCO Refractories offers a comprehensive line of refractory products, including fire bricks, insulating bricks, castables, and mortar. These products are designed to provide outstanding thermal insulation, durability, and ease of installation, making them suitable for a wide range of industrial applications.

Key Features and Advantages:

- Fire bricks and insulating bricks with excellent thermal properties

- Castables and mortar for various installation methods and applications

- Suitable for use in kilns, furnaces, boilers, and other high-temperature environments

Common Uses:

- Thermal insulation in high-temperature industrial equipment

- Lining and patching of furnaces, kilns, and boilers

- Backup insulation for dense refractory linings

Pocono Fabricators / SAUERISEN

Distributors of Pocono Fabricators and SAUERISEN products, offering a range of refractory and corrosion-resistant materials for the toughest environments. These products are engineered to withstand extreme temperatures, chemical exposure, and mechanical stress, providing reliable performance in various industrial settings.

Benefits:

- High resistance to thermal shock, abrasion, and chemical attack

- Ideal for applications requiring corrosion resistance and durability

- Available in a variety of formulations to meet specific application needs

Typical Applications:

- Linings for chemical processing equipment and storage tanks

- Corrosion-resistant coatings for industrial equipment

- High-temperature insulation for furnaces, kilns, and reactors

RATH

RATH combines tradition and innovation in a unique way. Our extensive product portfolio is made in-house at our facilities. By using select materials and precise processing techniques, we guarantee the highest quality. This results in perfectly suitable refractory solutions for a wide variety of applications in refractory construction, refractory insulation or blast furnace construction. Fireproof your business by working with us.

Reno Refractories

Reno Refractories provides a range of high-performance refractory products, including their LIQUIBOND series, which offers superior bonding properties for enhanced thermal and mechanical stability. Reno products are designed for use in demanding environments where strength and durability are critical.

Benefits and Applications:

- High bonding strength for improved thermal and mechanical stability

- Excellent resistance to thermal shock, abrasion, and chemical corrosion

- Ideal for use in steel mills, foundries, and other high-temperature environments

Specifications:

- Available in various formulations and sizes to suit different applications

- Custom configurations available for specialized needs

- Engineered for maximum durability and thermal efficiency

Vacuum Formed Shapes

Vacuum-formed shapes are lightweight, high-performance insulation products designed for high-temperature applications. We distribute a variety of vacuum-formed shapes that provide excellent thermal insulation, low thermal conductivity, and resistance to thermal shock.

Key Features:

- Lightweight and easy to install, reducing structural load

- High resistance to thermal shock and spalling

- Suitable for use in a range of high-temperature industrial applications

Applications:

- Insulation for furnaces, kilns, and other thermal equipment

- Backup insulation for dense refractory linings

- Used in environments where rapid temperature changes occur

Custom Distributed Products

We understand that each project has unique requirements. That’s why we offer custom-distributed products designed to meet your specific needs. Whether you need a particular size, shape, or formulation, our team is here to help. Contact us today to discuss your custom product needs and learn how we can provide a solution tailored to your project.

Why Choose Applied Refractory for Distributed Products?

When you choose Applied Refractory for your distributed refractory products, you’re partnering with a company committed to quality, reliability, and customer satisfaction. Here’s why our customers trust us:

- Full-Line Distribution: We offer a comprehensive range of products from leading manufacturers, ensuring you have access to the best materials for your needs.

- High-Quality Materials: Our distributed products are sourced from reputable brands known for their superior performance and durability.

- Expert Support: Our experienced team is available to guide you through product selection, customization, and installation, ensuring you get the right solution for your needs.

- Fast Turnaround: With our extensive inventory and reliable distribution network, we provide quick delivery times to keep your projects on schedule.

Get a Quote Today

Ready to find the right distributed refractory products for your application? Contact us today to request a quote or learn more about our products and services. Our team is here to help you find the perfect solution for your high-temperature needs.